The form on the grinding wheel depends upon the geometry of the areas that must be grind, whether they involve internal or exterior grinding. Also, The standard abrasive materials made use of on wheels are quartz, sand, garnet, and corundum.

But in case you wish to Reduce modest areas utilizing plastic or aluminum, and so are limited on space as well as a finances, then this distinct industrial machine could possibly be the just one for yourself. After assessment, we have largely good issues to say with regards to the Haas Desktop Mill with its function in mind.

Activate the main ability source, accompanied by the power source from the CNC system, then the facility provide of the servo system, And at last launch the crisis end button to minimize the impact on the electrical parts in the CNC system and raise its services lifetime.

Yet one more limitation of vertical machining center is they usually Have got a smaller tool potential. This means producers who employ vertical machining focuses may have to alter apparatuses just about every every now and then when compared to the people who utilize amount machining focuses. This will prompt expanded private time and diminished performance.

Should the temperature is higher than this, it could point out a challenge With all the lubrication and will be checked.

The desk is flat on which you place the workpiece directly or benefit from a couple of fixtures, by way of example, tricky clamping vises or milled aluminum parts.

When deciding on CNC machine tools, it’s imperative that you think about the standard components that should be processed. Despite CNC machine tools getting high flexibility and robust adaptability, they are able to only reach the ideal final results when processing certain sections under specified problems.

Feed price refers to the velocity at which the cutting Device functions together the workpiece all through its one rotation.

The process of pinpointing the Instrument’s motion route on a CNC machine Software is known as interpolation. It requires incorporating intermediate details concerning regarded points on the track, depending on a specified velocity and path, and controlling the workpiece table and Software to pass through these points.

Significant format design for generation and intense workload in machining of panels of various elements the place the two energy and precision overall performance are required. Pretty sturdy and low servicing, ...

The milling cutter is accustomed to machine several surfaces of your workpiece. Commonly, the cutter click here rotates all over its axis, whilst the workpiece and/or cutter moves in a very feeding movement.

You are able to refer to the vertical machine center being an industrial workhorse since it can provide components with Fantastic accuracy and shorter direct instances.

For the complete set of continuous casting and rolling equipment, large gantry milling machine and enormous CNC lathe are demanded.

It’s crucial to Notice that the choice of a particular CNC machine Resource will range based upon the brand, size, and configuration.

Haley Joel Osment Then & Now!

Haley Joel Osment Then & Now! Scott Baio Then & Now!

Scott Baio Then & Now! Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Tiffany Trump Then & Now!

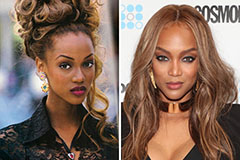

Tiffany Trump Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now!